manufacturing is hard.

With long lead times for material, machining, and processing, why wait till the final step to inspect parts?

At Coronado Manufacturing, an aerospace component manufacturing company, noncompliant parts frustrated machinists, managers, and customers.

Continue below to see the solution unfold.

Reduce quantity of noncompliant parts at final inspection.

Minimize lead time and cost of outside processing for rework and/or scrap parts.

Empower staff to take ownership of what they produce.

need:

Final inspection flooded with noncompliant parts, creating extra work for inspectors and materials review board.

Parts were sent for processing multiple times, both pre- and post-rework.

Critical features and dimensions for parts uncontrolled, with responsibility shrugged off downstream.

Root cause analysis showed parts became nonconforming as early as the first operation and every subsequent operation could make matters worse.

OBSERVATION:

Rewrite manufacturing routers to direct parts to outgoing inspection prior to shipment to outside processing.

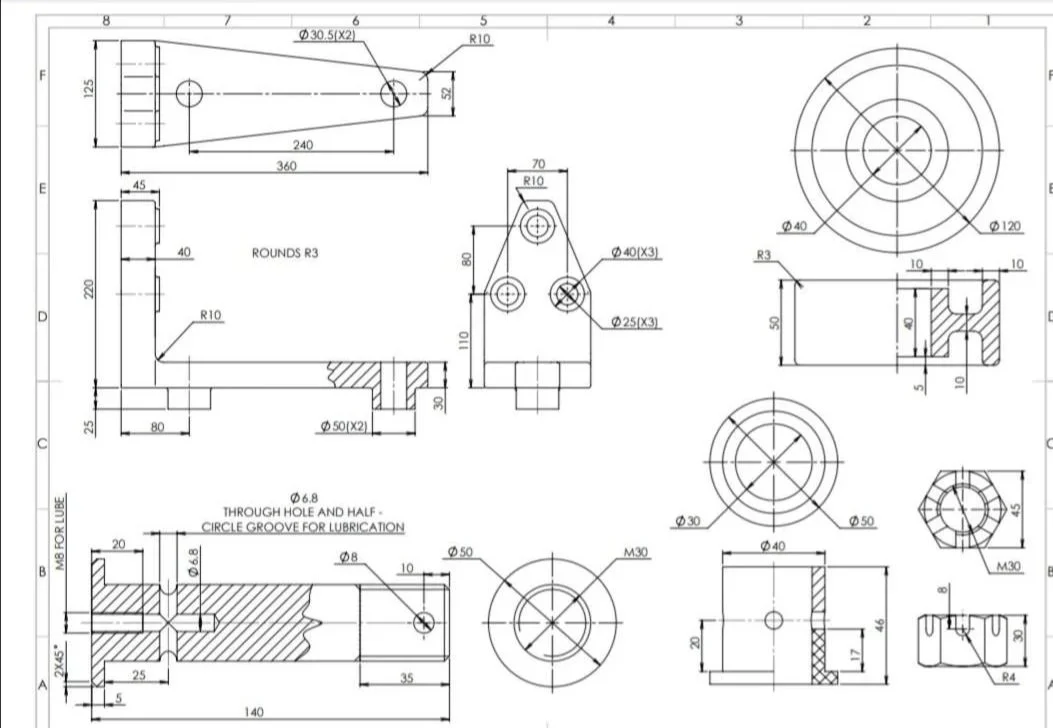

Create work-in-progress drawings to allow machinists to inspect parts quickly and efficiently based on their current operation.

Design and fabricate go/no-go gauges to test critical features from first cut to final inspection.

solution:

case study

case study

The aluminum housing pictured, below, required a fluid-tight seal with its mating parts based solely on the surface of the exterior walls. This proved extremely difficult to machine, as the tolerance for the flatness and parallelism of the walls needed to be within .0001” of each other.

To help mitigate this arduous process, the go/no-go gauge was designed to align with the holes in the exterior walls if, and only if, the walls were compliant with the tolerancing described above. Though the parts needed to be thoroughly checked at final inspection, this tool helped machinists check those holes on the fly. Empowered to check their own work, employees were able to flag nonconformances early—well before they ever made it to inspection.