3D PRINTING

In spite of traditional subtractive methods, additive manufacturing has been revolutionary for both rapid prototyping and full-scale production. Get a taste of my experiences with 3D printing below.

in the begiNNING…

there was modix

My first foray into 3D printing was at my summer internship at Modix Technologies, a producer of large-scale (print bed of over 1 cubic meter!) FDM printers.

While at Modix, I engaged in a multitude of projects to support modular improvements and add-ons to the flagship printer. These efforts included designing models to push the limits of the printer and discover new failure modes, writing a brand-new user and assembly manual, and creating a proof-of-concept for an optional secondary extruder.

In the video to the left, watch as the printer probes the bed as it runs its universal bed leveling program, optimized by yours truly!

living mechANICAL features

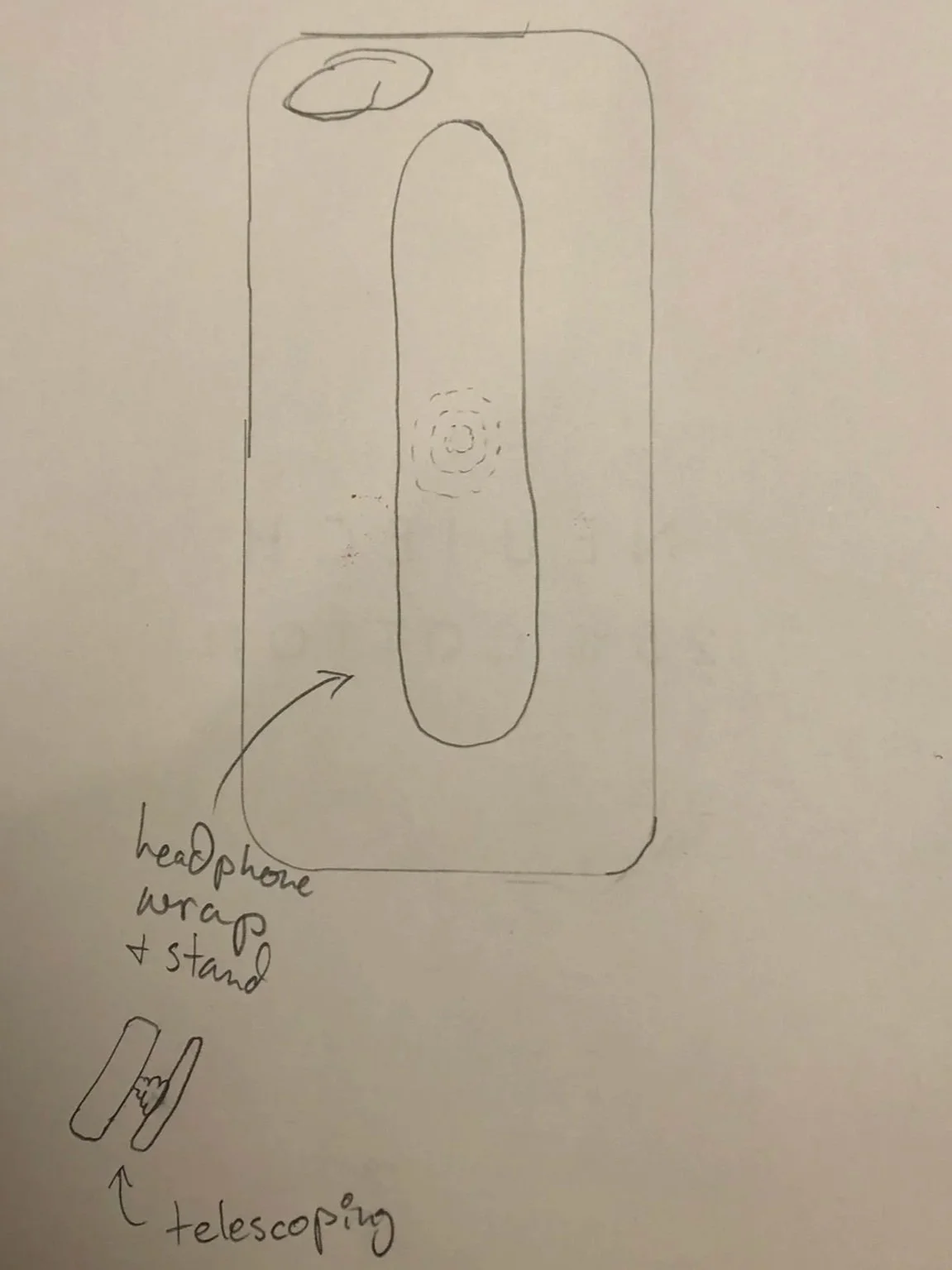

Case study: phone stand

Seizing the opportunities afforded by additive requires thoughtful design for manufacturing, iterative prototyping, and patience. To best achieve a telescoping design for a built-in stand in a phone case, I experimented with many different designs, shapes, and materials.

Using a variety of machines, including SLA and PolyJet printers, I was able to highlight the characteristics of different types of plastics and the key benefits to different printing approaches.

Attempt #1 SLA

Stereolithography is a fantastic option for creating highly-accurate parts and extreme overhands. For this project, however, SLA’s downfall was due to its capabilities. Since SLA uses one type of resin at a time, the case was too flimsy to protect a phone, or the telescoping stand was too rigid to flex.

Additionally, the stand’s design was incapable of keeping the phone upright at an angle. The size and shape were too trim and needed to be enlarged.

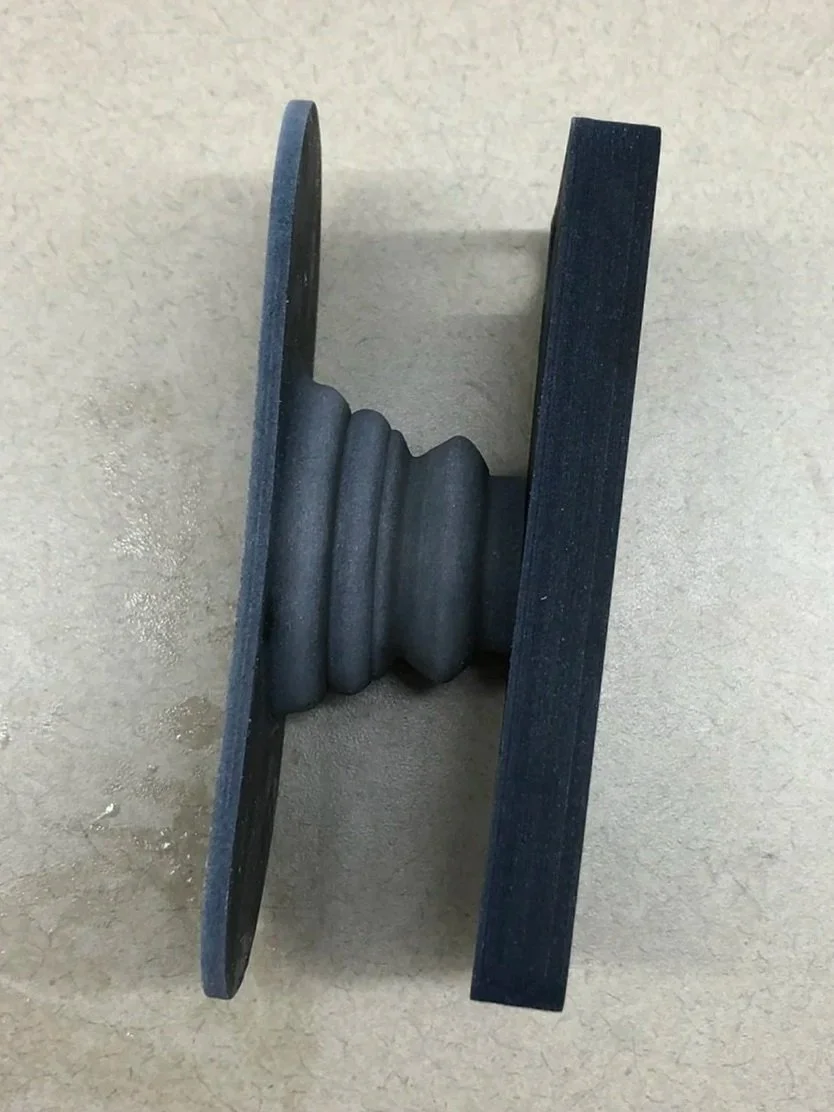

Attempt #2 polyjet

PolyJet was the obvious choice, given its flexibility for the types of usable materials, allowing users to print a myriad of different plastics. The combination of stiff case and flexible stand proved a major improvement over the previous iteration.

However, the entire stand was modeled and printed in one piece, meaning it was all the same material. During testing, I observed sagging around the edges of the stand. It was clear the same flexibility that empowered the living hinge was still creating issues for the case’s robustness.

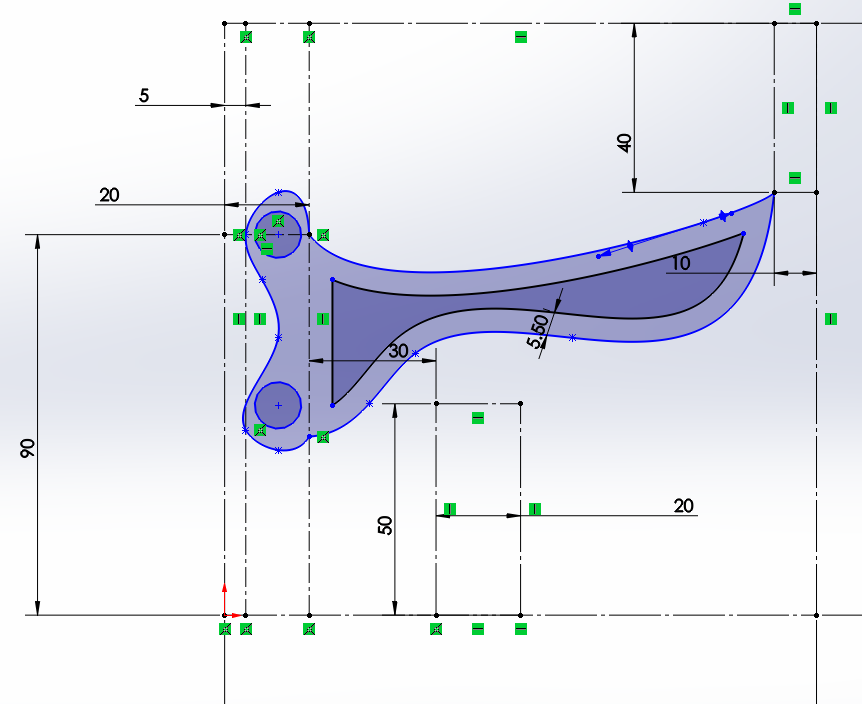

Attempt #3 polyjet again

By switching to a 3 piece design printed in one run, I optimized the rigidity of the case, the flexibility of the telescoping feature, and the performance of the stand.

To strengthening the portion of the stand that was load-bearing, I thickened the walls and used a more rigid plastic than my prior attempt. I also added multiple lofts and fillets, in an attempt to add more organic shapes to improve ergonomics. Lastly, the improvements made to the hinge (reducing wall thickness and increasing surface area contact between different materials) meant better adhesion between the pieces and increased endurance during fatigue testing.

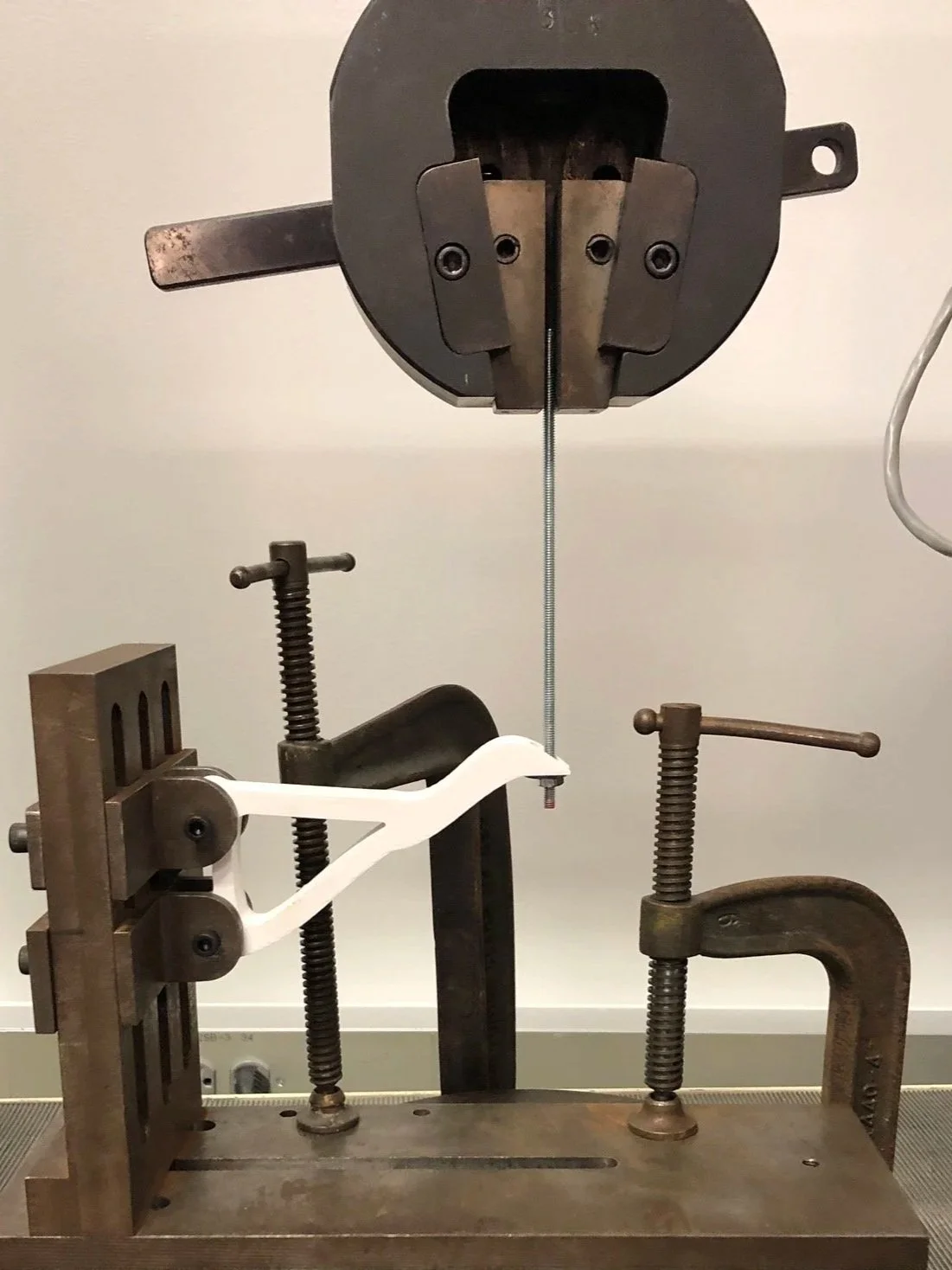

geometry, Nontraditionally

A key feature of all additive processes is their common ability to create entirely unique shapes and internal geometry.

I was empowered to create a shape freely, with the intention of FDM printing a bracket to maintain as much upward deflection as possible. Inspired by the natural curvature of the crane, I attempted two seperate designs, the second of which (pictured left) successfully sustained 22 lbs!

FDM prints

Wakaan Kandi (Bracelet Charm)

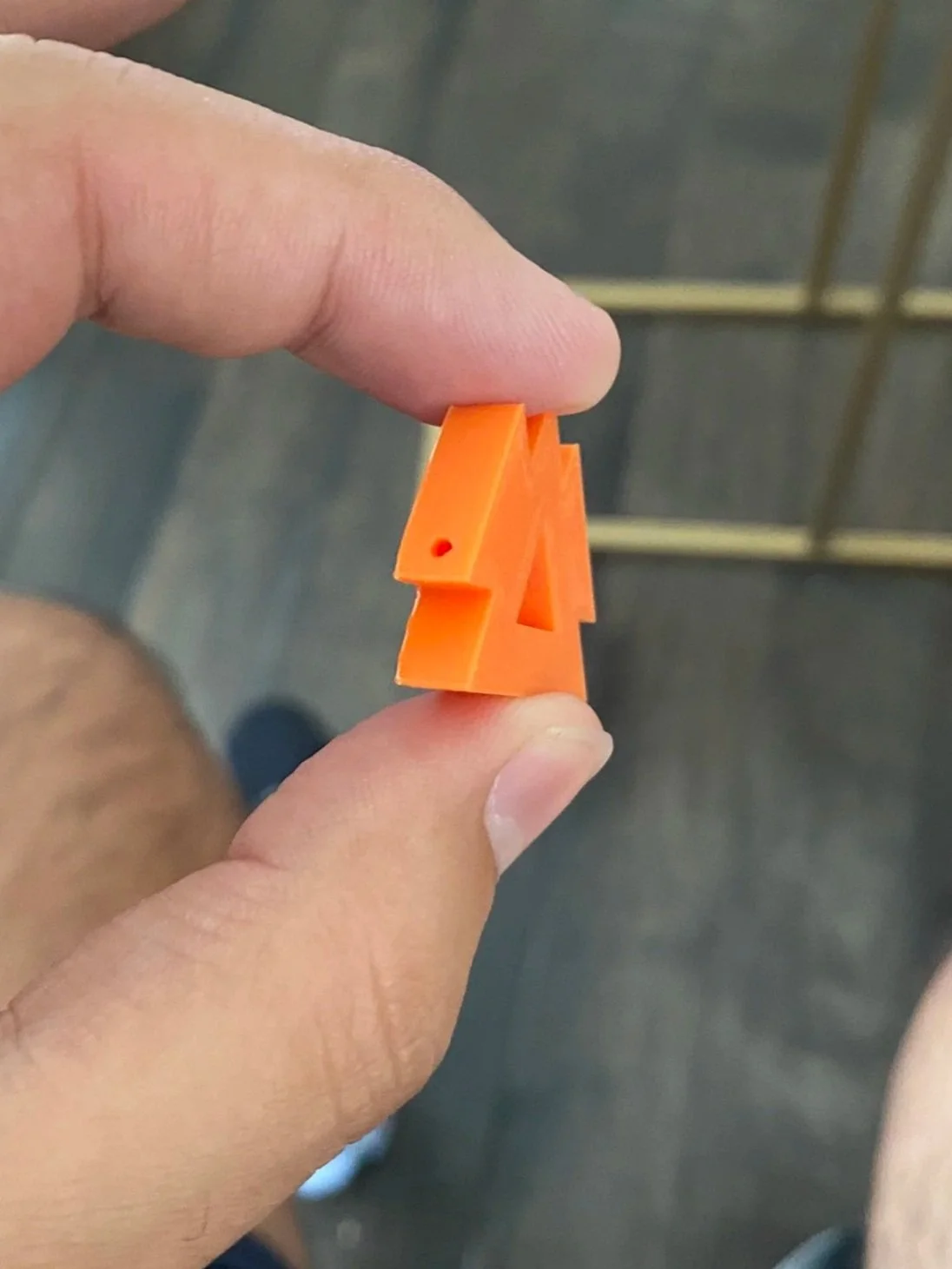

In-House Inspection Tool