CNC Milling

One of the most widely-used manufacturing methods, CNC machining (inclusive of mills, lathes, and grinders) has been an extremely important tool for manufacturing high-precision metal parts. Continue below to see some examples of projects completed with CNC machines.

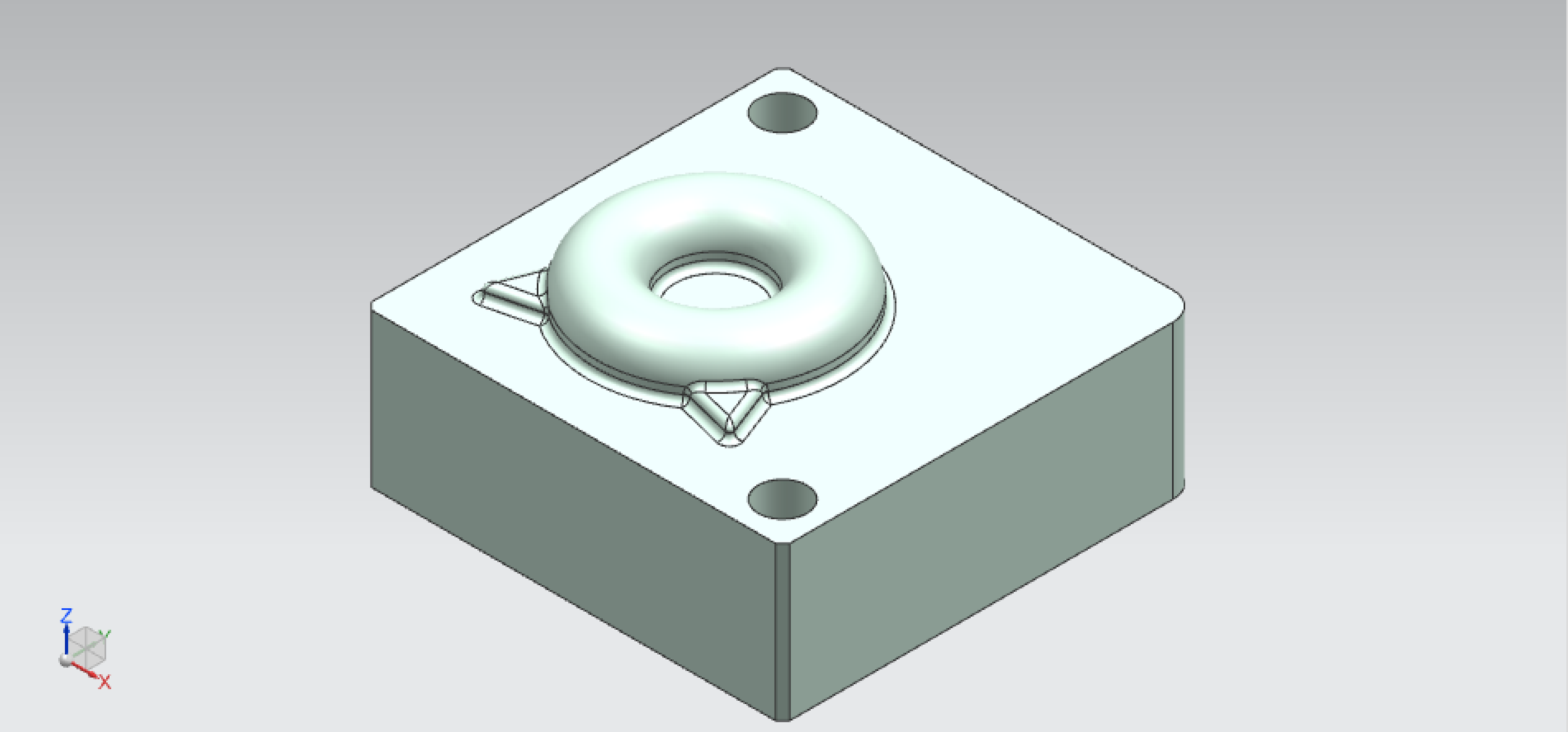

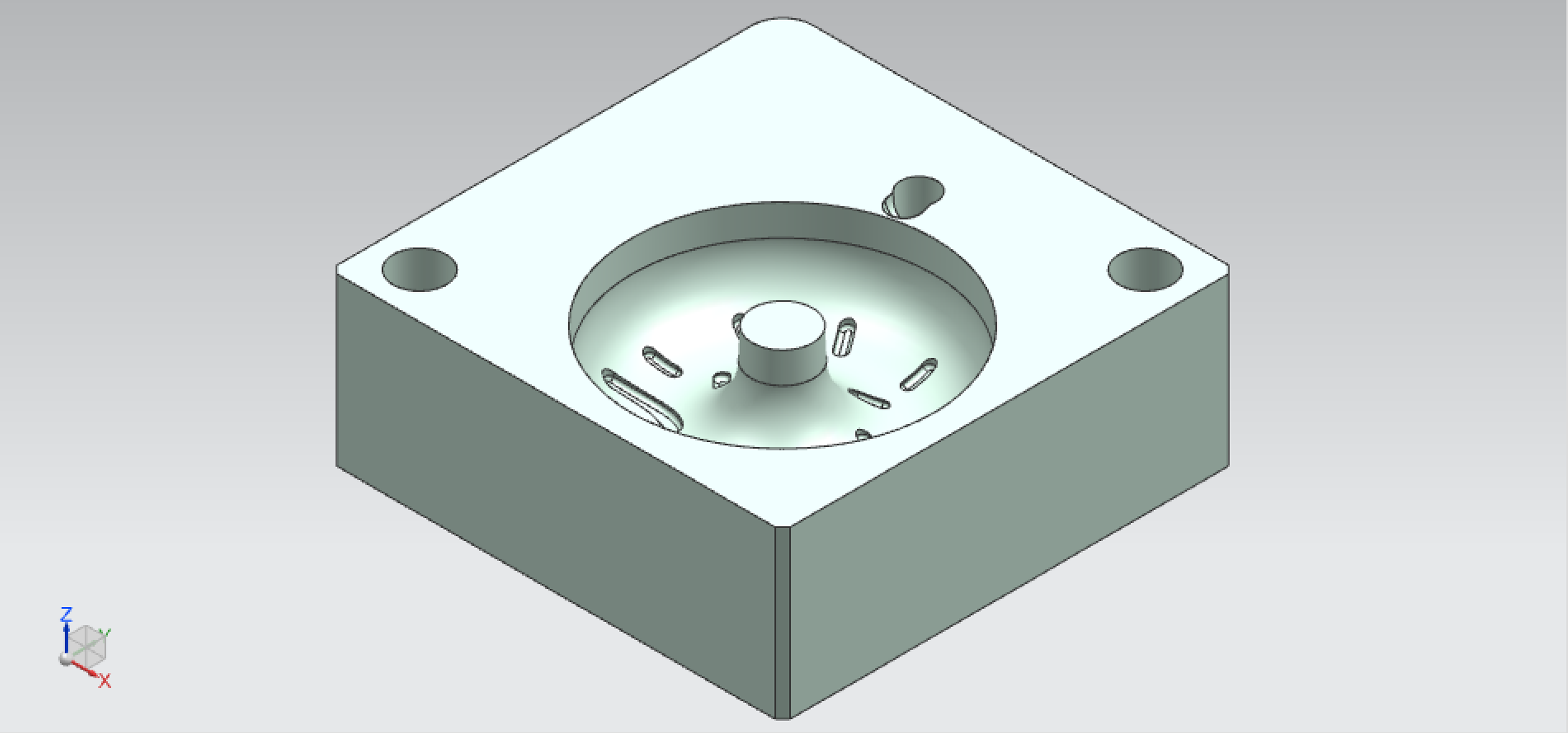

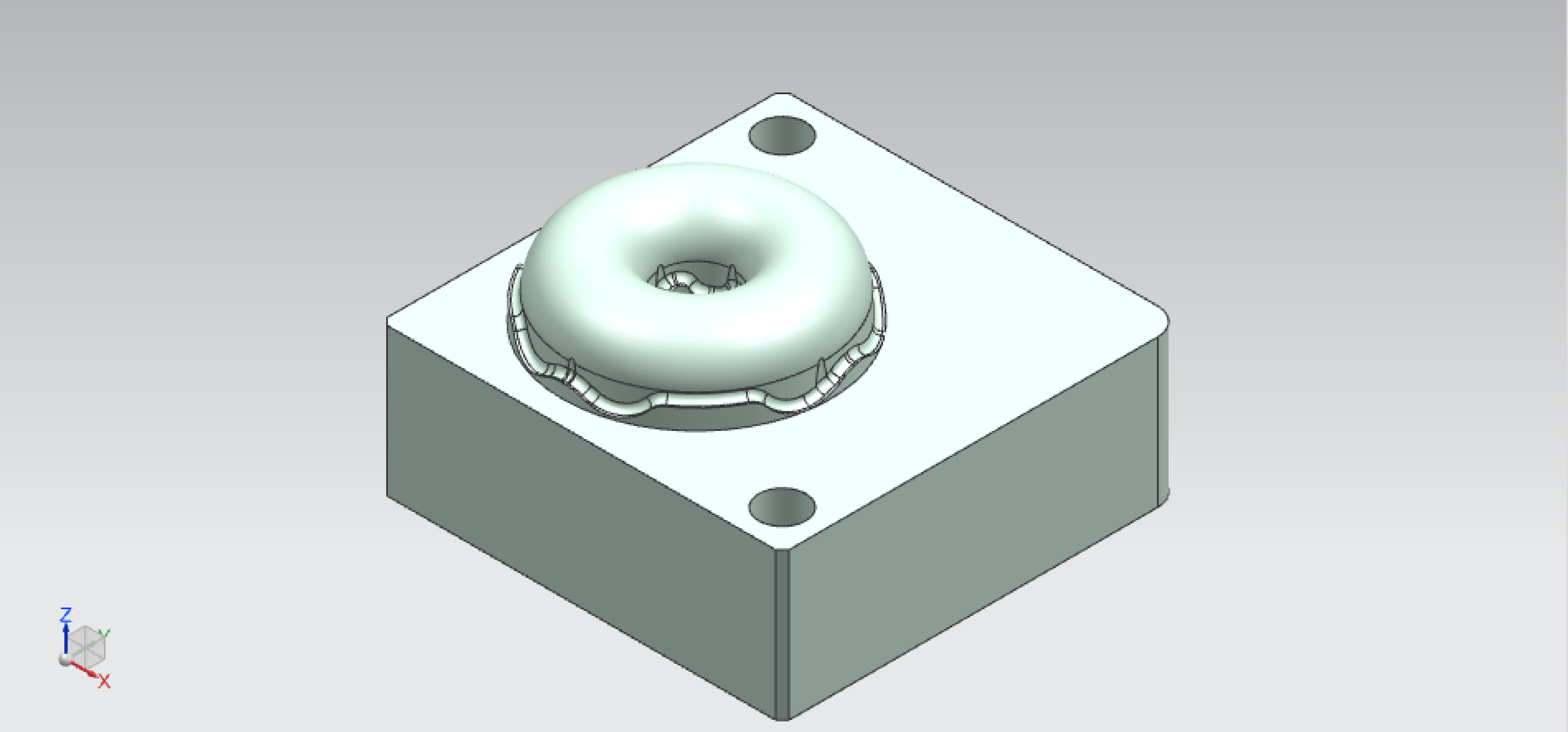

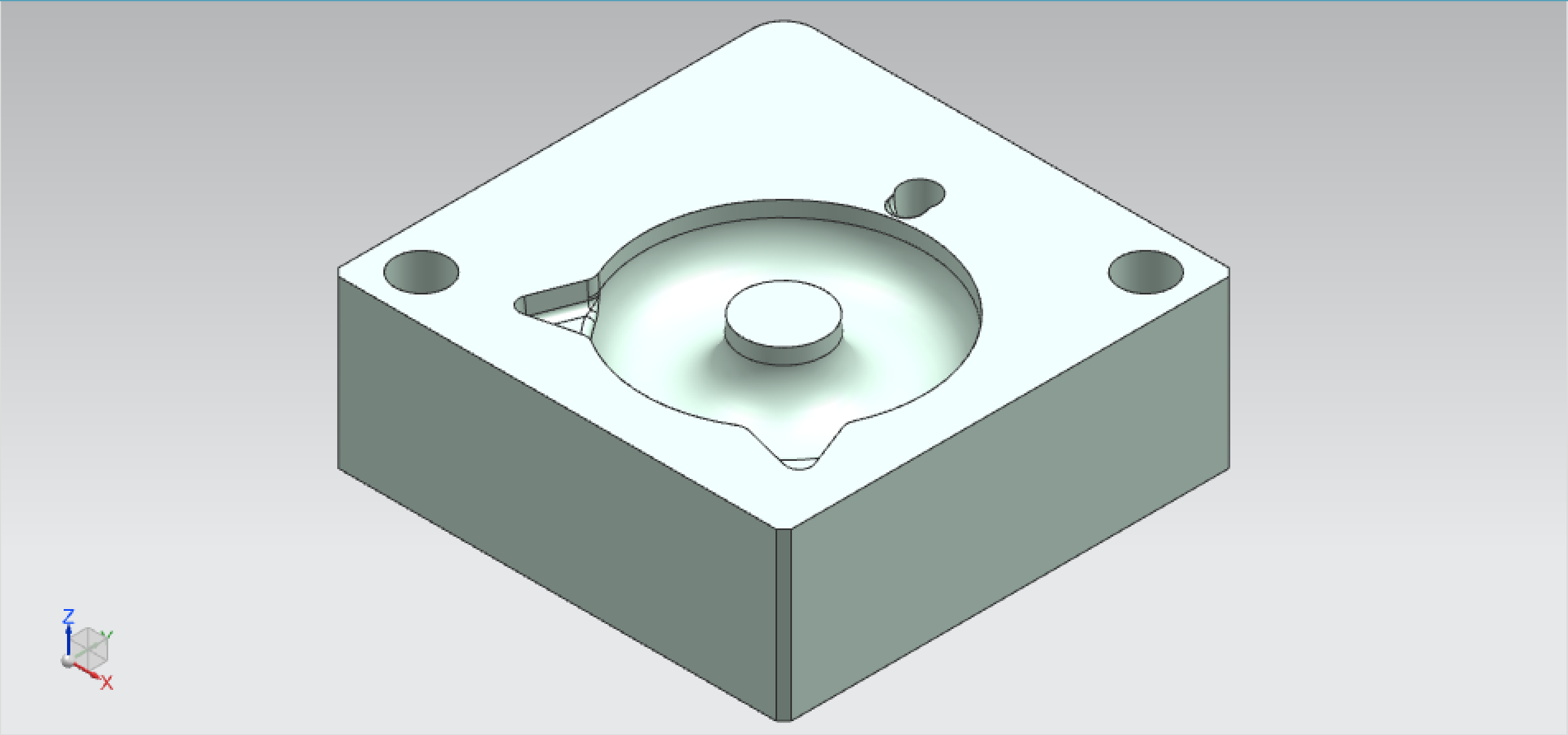

Cat donut molds

mold considerations

To create the final cat donut, we needed two sets of molds— a cavity and core for both the top and bottom piece.

A number of considerations were included in the molds’ designs to ensure manufacturability and ease of machining. The initial design choice centered the half-tori along the z-axis. This orientation minimized deep, curved pockets and removed potential undercuts.

Additionally, the parting line was shifted higher up on the top half, specifically to alleviate challenges to machining the wavey frosting edge. Rather than machining a depression to match the shape, a raised edge was used to maximize machinability.

The cores for the parts also including a generous 0.0625” fillet to make part ejection easier.

CHECK OUT THE FULL PROJECT BRIEFING ON THE CAT DONUT PAGE

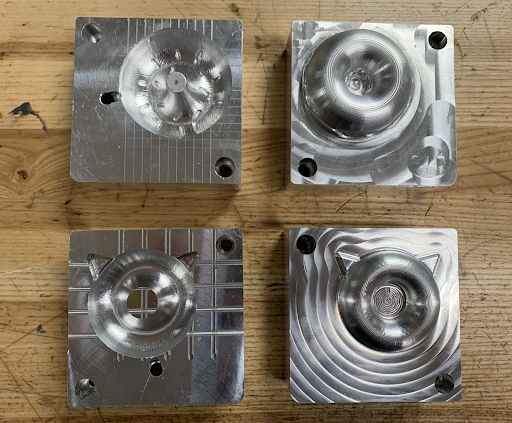

final molds

〰️

final molds 〰️

Pictured above are the actual molds used to create the cat donut. Click the links to find out more about the overall project and technical process for making the molds!

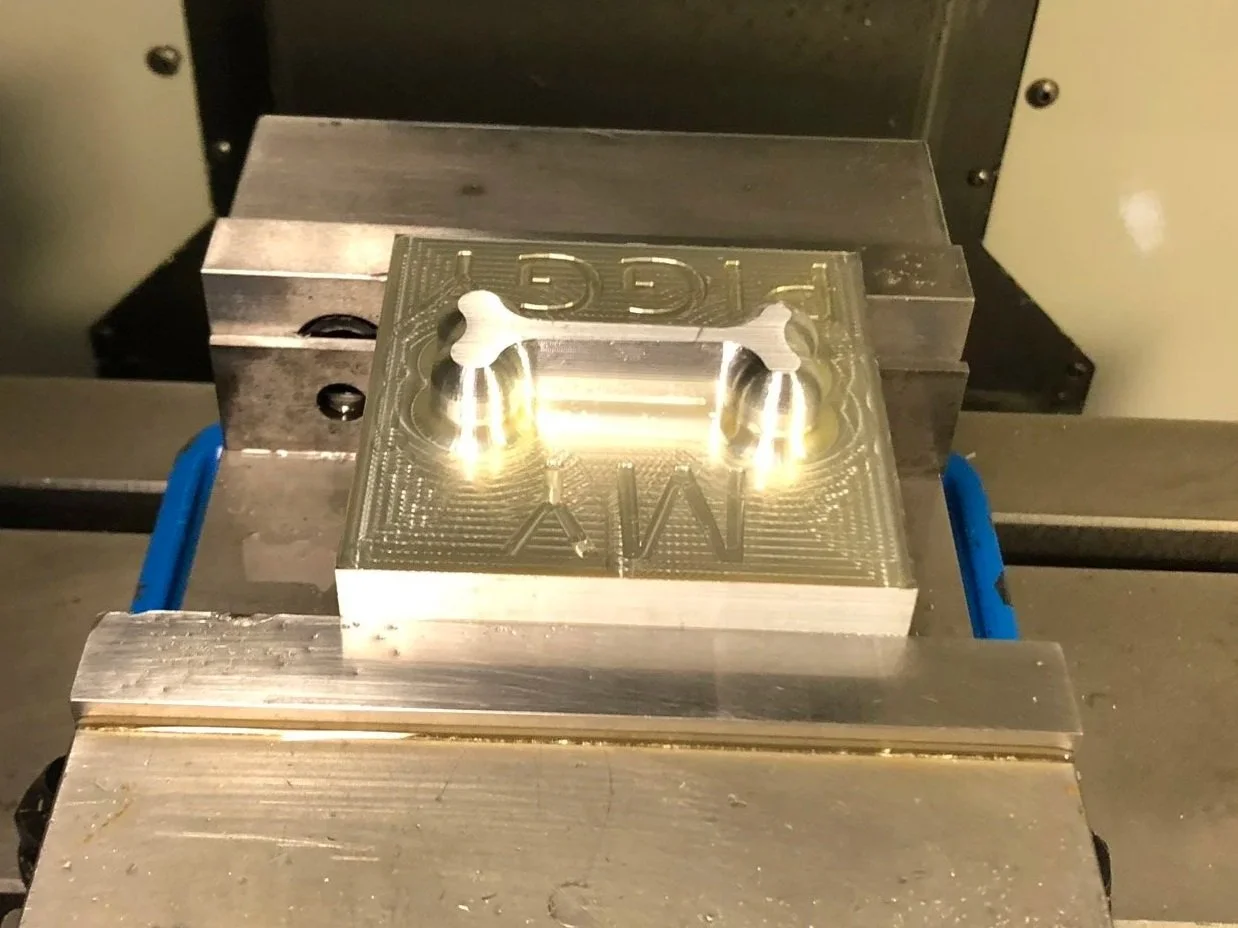

Pig, Immortalized

Not all projects need to be functional! Made as a tribute to my late dog and best friend Pig, this soft aluminum sculpture combines the smooth, polished curves achievable with high speed ball-end milling with the careful, low speed precision of engraving.